Understanding Machine Vision: Technologies, Applications, and Impact in Industry

The Fundamentals of Machine Vision

In today’s fast-paced industrial landscape, the need for precision and efficiency is more critical than ever. At the forefront of this evolution is machine vision, a technology that enables machines to interpret and understand the visual information in their environment. This capability not only enhances automation processes but also significantly improves quality control, ensuring that products meet the highest standards before reaching consumers. In this comprehensive guide, we will delve deeply into the fundamentals of machine vision, exploring its core components, operational principles, and the technology behind it.

What is Machine Vision?

Machine vision refers to the use of imaging technologies, algorithms, and systems to enable machines to “see” and make decisions based on what they observe. Typically employed in industrial settings, this technology incorporates cameras, lighting, and image processing software to interpret visual data. Machine vision systems are designed to simulate human vision to some extent, allowing them to perform a variety of tasks including measurement, inspection, and guidance in manufacturing processes.

Defined as the integration of hardware and software that processes images, machine vision systems provide critical feedback loops necessary for automation. By analyzing visual data, these systems can facilitate quicker decision-making and ensure consistent product quality, which is particularly vital in high-volume manufacturing environments.

The Core Components of Machine Vision Systems

A machine vision system typically comprises several critical components that work together to facilitate the visual decision-making process. The main elements include:

- Cameras: The eyes of the machine vision system, capturing images of objects or scenes. Depending on the application, cameras can vary in type (e.g., monochrome, color, 3D) and resolution.

- Lighting: Proper illumination is essential for producing high-quality images. Lighting systems designed for machine vision can include various technologies such as LED, laser, and strobe lighting, which can be optimized for different applications.

- Image Processing Software: This software interprets and analyzes the data captured by the camera. Advanced algorithms allow for tasks such as pattern recognition, defect detection, and object classification.

- Hardware Components: This includes the processing unit that may be a dedicated vision processor or a general-purpose computer capable of handling the computational load needed for real-time image analysis.

- Communication Interfaces: Machine vision systems must often interface with other machines or systems within the assembly line, which requires robust communication protocols.

Principles and Technologies Behind Machine Vision

The successful implementation of machine vision relies on various principles and technologies that enable effective image capture and processing. The core principles involve three key activities:

- Image Acquisition: This involves generating images of the objects to be examined. Image sensors in cameras convert light into electronic signals that form the basis for digital images.

- Image Processing: After image acquisition, processing begins. Algorithms analyze the images to extract relevant features necessary for the intended application, such as finding edges, segments, or patterns.

- Outcome Evaluation: Once images are processed, decisions are made based on predefined criteria. This may involve comparing inspected items to standards, and the results may determine whether a product continues down the production line or is rejected for rework.

Applications of Machine Vision Across Industries

The usage of machine vision technology spans numerous industries, transforming conventional practices and enabling better performance metrics. Below are key areas where machine vision is making a significant impact.

Quality Control and Inspection

One of the most prominent applications of machine vision technology is in quality control and inspection. Utilizing camera systems and image processing algorithms, companies can monitor product quality throughout the production process. This enables the detection of defects at an early stage, significantly reducing waste and ensuring that only products meeting specific quality standards reach the market.

For instance, in the food and beverage industry, machine vision systems can inspect packaging for proper seal integrity or verify label placement and legibility. In semiconductor manufacturing, machine vision is employed to detect flaws on wafers, ensuring process precision.

Automation in Manufacturing

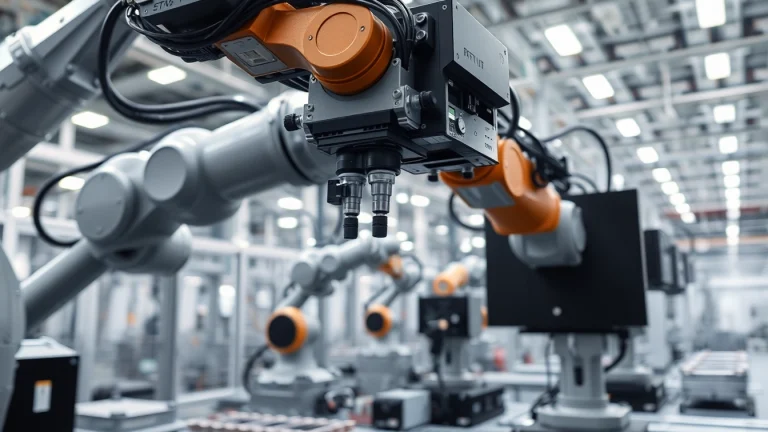

Automation, a cornerstone of modern manufacturing, relies heavily on machine vision technologies to enhance operational efficiency. With the capability to quickly guide and adjust machinery based on real-time feedback, machine vision systems enable faster production cycles and significantly reduce errors associated with manual inspection.

Applications include automated assembly processes, where machine vision systems can verify that components are correctly aligned and placed. Additionally, robots equipped with machine vision can autonomously navigate production floors, pick and place items accurately, and adapt to changing environments.

Emerging Trends in Machine Vision Applications

As technology evolves, so do the applications of machine vision. Emerging trends include:

- Integration with AI: Leveraging artificial intelligence, machine vision systems are becoming smarter, enhancing their ability to learn from mistakes and adapt to new situations.

- Cloud Computing: With advancements in cloud technology, machine vision systems can process data remotely, reducing the need for high computational power on-site and allowing for scalable solutions.

- Enhanced Mobility: Mobile devices equipped with advanced camera systems are allowing for machine vision applications outside traditional factory settings, such as quality inspections in agriculture or infrastructure.

Machine Vision vs. Computer Vision: Understanding the Differences

While both machine vision and computer vision utilize visual data for analysis, they serve distinct purposes and applications. Understanding the differences between these technologies is crucial for businesses seeking to implement vision systems effectively.

Defining Each Technology

Machine vision typically refers to the technology used to inspect and analyze objects in a manufacturing environment, often involving fixed systems that scan and evaluate products in real-time. In contrast, computer vision encompasses a broader field combining algorithms and machine learning techniques to interpret visual data, with applications extending to areas like augmented reality, facial recognition, and medical imaging.

Key Use Cases for Each Approach

Machine vision is predominantly used in structured environments where the tasks are well-defined. Examples include:

- Automated quality checks in production lines.

- Guidance systems for robots assembling or sorting products.

- Barcode scanning and verification at retail checkouts.

Computer vision, however, finds applications in more varied environments, including:

- Personal assistants interpreting user gestures.

- Driverless vehicles using vision systems to navigate.

- Healthcare applications, such as diagnostic imaging where interpreting complex patterns is critical.

Integration Opportunities and Challenges

The integration of machine vision and computer vision technologies can lead to enhanced capabilities. However, challenges remain, including:

- Data Quality: Ensuring high-quality input data is crucial for both machine and computer vision systems.

- Cost and Implementation Time: Integrating advanced systems often requires significant investment and time to train staff and optimize processes.

Best Practices for Implementing Machine Vision

To maximize the benefits of machine vision systems, companies should follow best practices during planning, installation, and operation.

System Design and Setup Considerations

Successful implementation begins with designing a system tailored to specific operational needs. Considerations include:

- Application Requirements: Clearly define the tasks that the machine vision system needs to achieve.

- Environment Conditions: Assess lighting conditions, space, and other environmental factors that may impact performance.

- Scalability: Design systems that can adapt to changing needs or technological advancements over time.

Software and Hardware Selection

Choosing the right software and hardware is critical for system effectiveness. This involves evaluating image processing capabilities, compatibility with existing machinery, and ease of use. Both proprietary and open-source solutions carry their distinct advantages and should be considered based on organizational needs.

Ensuring Optimal Performance of Machine Vision Systems

Post-installation, it is essential to monitor and maintain the machine vision systems regularly to ensure optimal performance through:

- Regular Calibration: Periodic calibration of cameras and sensors is necessary to maintain accuracy.

- Software Updates: Regularly updating software can improve efficiency and introduce new features.

- Training Personnel: Ensuring that operators are well-trained on the system’s functionalities to get the best results from the technology.

Future Trends in Machine Vision and Their Implications

Looking forward, the machine vision landscape is set for tremendous growth and transformation, driven by advancements in technology and changing industrial needs.

Advancements in AI and Imaging Technologies

The convergence of artificial intelligence and machine vision is one of the most promising trends. As AI algorithms become more sophisticated, the capability of machine vision systems to conduct complex analysis and adapt to variations in production will expand. This evolution leads to increased efficiency and reduced downtime in manufacturing processes.

The Role of Machine Vision in Automation and Industry 4.0

As the manufacturing sector pivots towards Industry 4.0—which emphasizes smart automation and connected systems—machine vision will play a pivotal role. Integration with the Internet of Things (IoT) will allow for more responsive manufacturing environments, where machines communicate and collaborate seamlessly, enabled by real-time visual feedback.

Future Challenges and Opportunities for Machine Vision

Despite the vast potential, machine vision systems will face challenges such as:

- Data Privacy: Decision-making based on visual data will heighten concerns regarding privacy, especially in sensitive environments such as retail and healthcare.

- Integration Complexity: As systems grow increasingly interconnected, ensuring compatibility between diverse technologies can be complicated.

However, addressing these challenges will create opportunities for innovations that push the boundaries of what machine vision can accomplish across various industries.